How to measure the steel wheel and what should be considered when changing the it.

If you were thinking about changing your truck’s steel wheel due to the it was broken, worn out or too old to be used. For all the owner who could not find the manual or lost it and did not know the size of the truck’s wheel. Today, we would like to give you an advice for measuring the wheel so you can find the suitable steel wheel for your truck.

The wheel parts which you have to consider

- Size of wheel – Which measure by diameter

- Number of bolt hole – Which could be 4, 6, 8 and 10 holes.

3. Type of bolt hole – Generally, the wheel contains with 1 of the 3 sizes of bolt hole such as small, medium and large for holding bolts 26ISO, 27SR18, 27SR19, 32SR22, etc. .

- Inner hole core – The size of wheel hub for each brand and year are different, so the size of the inner hole core and the hub should be the same.

- Outer hole core or P.C.D range will be mention later

- Wheel surface

- Taper – Which the wheel could contain or not, it will be mention later.

*For the size of hole and inner hole core, look at the P.C.D measuring example for five holes and ten holes steel wheel.

P.C.D

P.C.D stands for Pitch Circle Diameter means the distance of holes on the wheel by measure from the center of each hole as in circle, then measure the diameter of this circle by millimeter. If the wheel has 4 or 6 holes, you could measure from the center of 1 hole to the opposite hole. But if the number were 3 or 5, you have to measure from the center of each hole as in circle. The smaller car usually has 4 holes a wheel and the bigger car has 5-6 holes for tightly mounting the wheel and the hub.

Many people wonder why the P.C.D measurement is different. In the past, the car inventor of many companies from Asia, Europe and America had invented and designed their own car by the brand’s agenda which assumed that they used inch as the measurement. But later, some countries use metric as the standard measurement so they designed the wheel that can be measure in millimeter.

Measuring P.C.D by yourself if you want to know the P.C.D range of your wheel. You can measure it by these easy way :

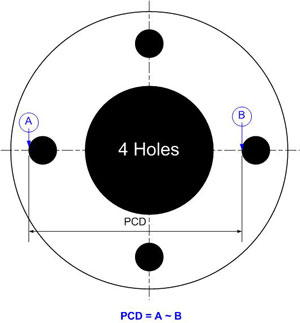

For 4 and 8 holes wheel

– You can do it by measuring from point A to point B and see how much for its range like it shows 100 mm. this is the P.C.D range for your wheel.

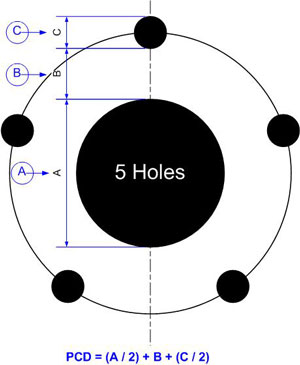

For 5 and 10 holes wheel

– The measuring for 5 and 10 holes, have to do a little calculation. From the example, it shows all positions which you have to measure.

(A) is the diameter of the center bore.

(B) is the range from the edge of center bore to the edge of bolt hole.

(C) is the diameter of bolt hole.

The formula = (A divided by 2) + B + (C divided by 2)

Example

A = 110, B = 58,5 and C = 13

(55) + (58.5) + (6.5) = 120 (This is the P.C.D range)

For 6 holes

– The measuring for 6 holes is similar to 4 holes by measure it from point A to point B.

รู PCD

– ล้อใหม่ที่เราจะเลือกใช้ ต้องตรงกับสเปคของรถนั้นๆ ไม่ควรดัดแปลงค่าใดๆ ทั้งสิ้น เพียงเพราะความชอบส่วนตัว หรือความสวยงามของล้อแม็ก

P.C.D Hole

– Your selected new wheel must be matched with your vehicle and should not do any modification because of personal preference or nice looking wheel.

Hub Diameter

– The center hole of your wheel must be match for the hub diameter. Not too tight and not too loose.

The load

– You should choose the wheel which appropriate for the job and loading.

Mounting the wheel with the hub

– The wheel that you choose, the bolt holes must be perfectly match with the hub and be the same type as the design.

Related Parts

– When choosing the wheel, it should not impacted with other parts such as shock absorber, fender, wheel, control arm, etc. .

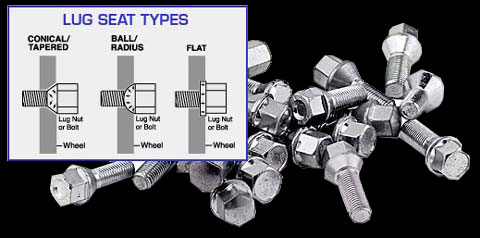

Nuts and Bolt

– Nowadays, most of the vehicle owners did not know which type of nut and bolt is appropriate. For being more safety, validity, suitability of the equipment which make the vehicle runs smoothly and safely, sometimes the old bolt could not be used with the new wheel. So you have to choose the suitable one. Otherwise, it will reduce the mounting strength of the the wheel and the hub. It would cause an accident or damage the vehicle.

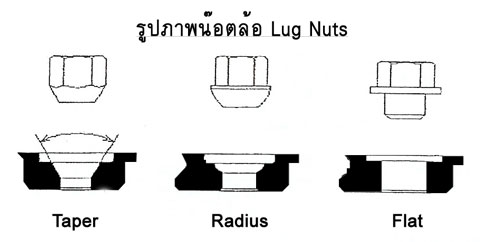

The type of lug nuts

1) Taper

– It was designed to have 60 degrees angle. If the P.C.D hole is an angled design, you must use taper.

2) Radius or Ball

– The point of this type of bolt is a round shape design, suitable for round shape P.C.D hole.

3) Flat

– The point of this type of bolt is flat shape design, suitable for flat shape P.C.D hole.